Solidworks - Easy Resin Print Supports

The biggest issue I have had printing small parts is bed adhesion. LycheeSlicer comes with some powerful automatic tools for building supports, unfortunately they don't know which surfaces are important and they raise the part off the bed surface which ruins one very valuable reference surface.

My solution has been to painstakingly apply custom supports in Solidworks, by mimicking the automatic tools of LycheeSlicer. But last night I developed a better method.

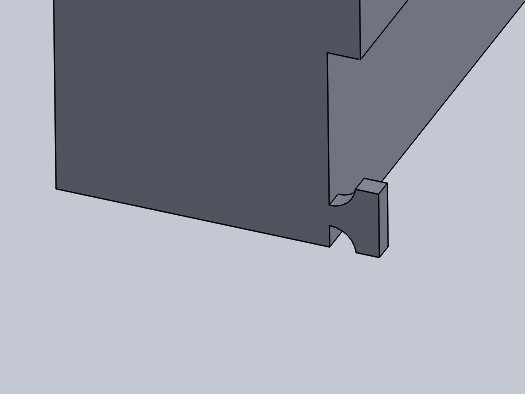

1) Create a feature which will easily break from your printed part.

2) In a new sketch plane on the build plate side of your part, offset the profile of the part. Replace all the sharp edges of the offset with radii. I find the simplest tool for this job is the sketch fillet. Exit the sketch.

3) Select your support feature and add a curve driven pattern. Play around with the settings until it looks right, and you should have something like this:4) Build a raft around your supports. Et voila!:I skipped a few instances of the support pattern. Your mileage may vary. My part features were too small for the burn-in layers, but the technique is sound. If you do a resin print test you will have specific information about the feature size of your prints. This was my first successful vertical print, and the result was encouraging. Despite the supports being a single piece they were easy to remove and there was minimal post-processing.

Comments

Post a Comment